Case Study

CargoVIS in cargo handling

at DGS Transports

Case Study

CargoVIS in cargo handling

at DGS Transports

"The cooperation with DIVIS was a success. In the future, we will rely on DIVIS solutions because they are a perfect match for our tasks."

| Ludovic Charlec Chief Operations Officer at DGS Transports |

|

|---|

20 March 2024

French logistics company significantly increases efficiency in handling processes

CargoVIS with indoor positioning enables high quality standards at DGS Transports

Continuously growing shipment volumes paired with tightly calculated delivery times are the standard in today's logistics world. Looking at the sheer volume of goods, it is not uncommon for a consignment to be lost or take an unplanned route. As a consequence, it is essential for transport companies to always have a complete overview of their shipments - across all flows of goods. Obviously a purely manual search without any additional tools is simply far too complex and time-consuming with such an abundance of consignments. It is therefore important to rely on smart, intuitive technologies.

For this reason, the French freight forwarding company DGS Transports was also looking for a suitable solution to track the goods in the 6,000 square metre cross dock conveniently, quickly and reliably. The transport specialist became aware of DIVIS through its German partner companies in the CargoLine general cargo network and opted for its CargoVIS video management solution in combination with the Location+ plus feature module, an indoor positioning system developed by DIVIS partner Quuppa. Therefore, the video management system (VMS) from DIVIS is not only being used by many French customers in the parcel industry, but also increasingly in the French cargo market.

Highest level of quality and service for customers

It is not surprising that DGS Transports, based in Limeil Brévannes (Paris), decided in favour of this system. After all, software-based video management systems provide valuable services in the forwarding industry. Furthermore, the seamless consignment tracking, which is provided by this technology become an integral part of everyday logistics. Precise indoor positioning plays an important role here. "Our reasons for choosing a visual consignment tracking system with indoor positioning are closely linked to our objectives in terms of quality and customer service.” explains Ludovic Charlec, Chief Operations Officer at DGS Transports. "We needed a solution that was easy to learn for our employees and at the same time extremely efficient in terms of time expenditure. The advantage of indoor tracking is that we can locate all goods as quickly as possible and follow their movements," he continues. Not only the quality of service can be significantly increased but also the flow of information can be made more transparent with the help of shipment tracking. As a result, customer enquiries can be answered quickly and reliably, even rare discrepancies can be clearly traced in the shortest possible time thanks to the system.

Precise consignment tracking thanks to a seamless movement path

DGS Transports uses the CargoVIS video management solution with indoor positioning from DIVIS partner Quuppa. A total of 60 cameras records every movement of goods within the cross dock. As a key feature this innovative VMS replaces time-consuming conventional investigation for consignments in the cross dock. The intuitive video management software offers image-based tracking, allowing palletised consignments to be traced and quickly located. Even if a consignment has already left the cross dock, its path can still be traced afterwards thanks to CargoVIS using the video recordings. Uncertainties regarding transfers of liability and missing consignments is now a thing of the past: With the VMS, critical points can be reliably documented, and losses can be reduced.

How the shipment investigation in CargoVIS works

By automatically linking the shipment data from the transport management system with the image data, each consignment leaves its individual "fingerprint" in CargoVIS with every scan. As the consignment passes through the hall, a movement path of information is created, enabling the goods to be tracked specifically and precisely in the cross dock via scan times - by entering the consignment or pallet number.

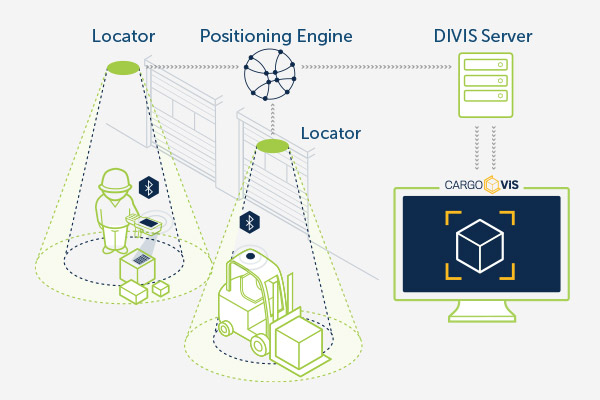

How Indoor positioning with Location+ works

The concept of indoor positioning with Location+ is comparable to that of satellite-controlled GPS outdoors. When locating with GPS, GPS receivers retrieve coded radio signals from satellites orbiting the earth, allowing precise positions to be determined. While GPS is sufficient for rough tracking outdoors, much more precise methods are required inside buildings. For the indoor positioning of shipments, Bluetooth is often used. Quuppa's indoor positioning system (Bluetooth tracking) is one of the most proven positioning methods for enclosed areas and offers many advantages for logistics. With this method, infrastructure devices - so-called locators - take on the role of satellites and an application on the scanners - the so-called BLE app – performs the task of GPS receivers. Indoor positioning makes it possible to determine the position of scanning processes with an accuracy of up to +/- 50 cm.

Thanks to the combination of location data, scan data and the recorded video footage, the system can identify the exact scanner position or the positioning area in the cross dock and enable fast and efficient investigations.

Enormous time savings and increased efficiency of warehouse processes

The precise recording of the position of goods using Location+ significantly increases efficiency in the warehouse. "The combination of CargoVIS with indoor positioning enables us to save an enormous amount of time in many processes," says Emmanuel Houelleu, Platform Manager at DGS Transports. " For example, if a colleague is searching for a pallet at the dock, with the inbound scan we can track the pallet and indicate where the pallet is," he emphasises. " Since we can easily locate the goods, we are confident about our actions. We can back up all the information we give to employees or customers with screenshots."

"The combination of CargoVIS with indoor positioning enables us to save an enormous amount of time in many processes."

Emmanuel Houelleu

Platform Manager at DGS Transports

German quality ensures great satisfaction

The French company was particularly impressed by the quality of the product. "We are very satisfied with the solution. It's a system that's very easy to use, and really simple to learn. It's very, very useful on a daily basis, especially in my role as a Platform Manager," reports Emmanuel Houelleu. Chief Operations Officer Ludovic Charlec is also satisfied: "We chose DIVIS as our provider because our German partners often used DIVIS systems. We are an official member of the CargoLine general cargo network in the Paris region. Therefore, we were able to see this solution in use at our partners' premises. That was a sign of trust and success for us."

DIVIS guarantees local support at all relevant customer touchpoints in France. In addition, DIVIS operates its own team for the French market, which supports customers from sales and project management to after-sales service in French.

Data platform replaces stand-alone solutions

Various additional modules - known as Plus+ features - allow different camera-based automations to be mapped and fully integrated via a single platform. This unique platform incorporates the Plus+ functions fully into the software solutions, eliminating the need for a multitude of stand-alone solutions. As a result, a wide range of data is collected along the goods flow in the warehouse, generating comprehensive added value for logistics processes.

In addition to Location+ for indoor positioning, the available Plus+ modules also include volume control of goods (Scale+) and gate status detection (Gate+), which is also used by DGS Transports. As a result, DGS Transports has access to an extensive ecosystem of different camera-based solutions.

The combination of the collected data (e.g. video, location and measurement data) opens up extensive optimisation and savings potential for logistics processes. This increases the quality of logistics services while valuable time and cost savings can be realised at the same time.

Here's how the volume control with Scale+ and the detection of gate status with Gate+ work

With the software-controlled volume control in Scale+, it is possible to measure pallets without interrupting the loading process. The measurement is based on the evaluation of previously recorded video footage, allowing measurements to be taken directly in the software.

Gate+ makes it possible to automatically detect gate and door statuses and close security gaps.

Conclusion

DIVIS platform excels through versatility

The DIVIS solution has impacted the French company positively in several areas at once - its success as well, as Ludovic Charlec reports. The Chief Operations Officer is also enthusiastic about the cooperation: "The cooperation with DIVIS was a success. In the future, we will rely on DIVIS solutions because they are a perfect match for our tasks. They offer us a number of possibilities, such as monitoring and dimensioning, all in the same interface. It really is a guarantee of confidence and sustainability in the performance of these activities," he summarises.

BACKGROUND

DGS Transports

DGS Transports, an independent, family- owned, medium-sized transport company, is based in Limeil Brévannes (Paris) and was founded in 1983. It specialises in courier and cargo transport throughout the national and European sector. Thanks to its medium-sized structure, the company can set and successfully defend strong values: high-quality services, versatility, responsibility and commitment of its staff as well as proximity to customers, suppliers and employees. DGS Transports is a member of the CargoLine general cargo network and a founding member and main hub of the TSE network in France.