Case Study

CargoVIS in the warehouse

at Gebrüder Weiss

"CargoVIS can be operated very

intuitively with regard to the search

of consignments and overall, the

software frontend feels more

modern for the user."

Markus Nigsch

Authorized Representative at Gebrüder Weiss

November 13, 2017

Gebrüder Weiss

Safe without searching

"The video surveillance is highly valued by our customers and partners CTL and Dialog and is as indispensable to us as a fire alarm system."

Markus Nigsch | Authorized Representative at Gebrüder Weiss

With video surveillance in the transshipment warehouse, Gebrüder Weiss speeds up the handling of outgoing goods and clarifies customer complaints, inventory differences and claims. At the branches Memmingen, Aldingen and Wolfurt, a DIVIS solution is in use.

In the turnover warehouse every minute counts. And it is all the more annoying when time is wasted during truck loading with the search for individual Colli. Against this background, the global logistics service provider Gebrüder Weiss has equipped many of their sites with video surveillance solutions. They connect the cameras mounted on the hall gates with the mobile handheld scanners of the employees and the forwarding software. This "marries" every barcode scan between incoming and outgoing goods with video footage of the particular Collis. If a package can not be found later, its path can seamlessly be traced and localized based on the parcel or consignment number and a special evaluation software.

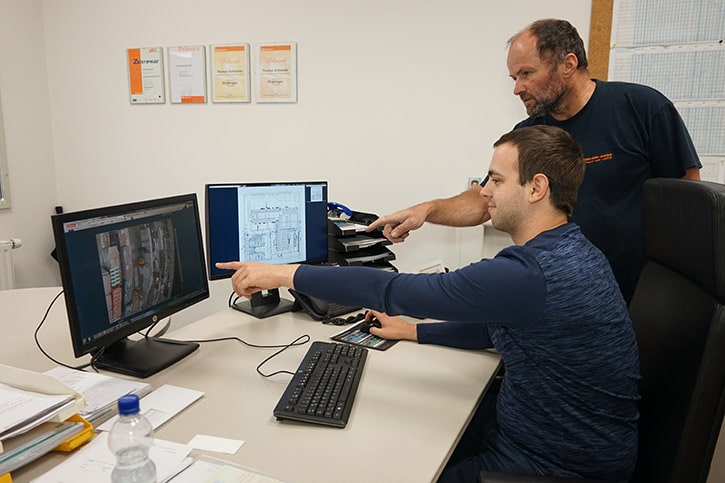

Through various acquisitions of the rapidly expanding family business, Gebrüder Weiss uses various video systems. However, the three most recent installations at the Memmingen, Wolfurt and Aldingen sites are all from DIVIS. The technology provider headquartered in Bordesholm was able to to beat the competition in the competitive biddings with the solution CargoVIS, the video management software for transshipment warehouses. "CargoVIS can be operated very intuitively with regard to consignment research and overall the software frontend feels more modern for the user," explains authorized signatory Markus Nigsch (picture on the right), who is responsible for real estate and facility management at Gebrüder Weiss.

Versatile Use

CargoVIS for video surveillance in the transshipment warehouse is working around the clock at Gebrüder Weiss and stores the data records consisting of consignment numbers, time stamps and camera positions in a local database. In Memmingen alone, it is accessed about ten times a day. With around 500,000 consignments with more than 1.5 million Colli per year, it frequently happens during loading that drivers can not find individual parcels. In these cases, the drivers turn to a dispatcher who uses CargoVIS and who uses the parcel or consignment number to determine the current position of the Colli in question and provides proof with photos.

The research not only speeds up the processing of outgoing goods, but also clarifies customer complaints, diesel thefts, claims and inventory differences. "Just a few weeks ago, with the help of CargoVIS, we were able to prove to a major customer that we had received less goods than the customer claimed to have delivered," emphasizes Operations Manager Thomas Schneider.

Deterrent effect

The data basis in Memmingen is provided by 82 cameras in two halls and 48 additional outdoor cameras, whose video material (3 frames per second) is stored at Gebrüder Weiss for 30 days. With this installation alone, all events at the gates and ramps can be traced, which has a deterrent effect on thieves. "Diesel theft is a thing of the past for us," confirms Schneider (pictured right), one of the positive effects of seamless video surveillance in the transshipment warehouse.

In addition to the efficient handling of huge amounts of data, the sophistication of CargoVIS is above all in the evaluation software and the targeted control of the respective "correct" camera group. In principle, DIVIS offers two solutions: In the automated version, each barcode scanner is located separately and assigned to the camera group in the respective hall section. Without any further action by the employee, on each scan the camera "with an eye" on the respective goods is assigned, and its images are linked with the consignment number.

Pragmatic solutions

Gebrüder Weiss opted for the second variant, in which the matching camera is linked through scanning of a barcode attached to the respective hall gate. This action must be carried out by the employee only once at the beginning of his activities in the work area. Thereafter, all scanned shipments are automatically assigned to the camera in question. "The pragmatic solution has proven its worth in everyday life, especially since our employees concentrate on loading and unloading anyway on a single gate," says Schneider.

Similarly pragmatic and sophisticated is the status control offered under the name "Gate+" for the 80 sectional doors. These have a white sign on the inside with a black framed circle that moves up and down when opening and closing. "The cameras detect when the circle is in the lowest position, which means when the gate is closed," explains Schneider. This information is permanently transmitted by CargoVIS to a dashboard that displays all gate positions at a glance. "This saves us a lot of time when closing the site at night and provides additional security," says Schneider.

Secure Data

Gebrüder Weiss also played it safe from the beginning when it came to data protection. Faces and the public areas outside of the property picked up by the outdoor cameras can easily be made unrecognizable by CargoVIS. In addition, only specially trained employees in selected departments can access the evaluation software. "We only installed the software on isolated PCs in the customer service, the local transport department, the claims department as well as the logistics and IT department," says Patrick Pflotsch (pictured right) from the IT Service Desk.

At Gebüder Weiss, the data expert is the internal contact for all matters relating to CargoVIS and the "interface" to DIVIS customer support. So far, Pflotsch has only had the best experience: "The DIVIS technicians are always available when needed and offer quick help," confirms Pflotsch. Since the launch of the plant in August 2016, however, he only needed to seek support twice.

Smooth installation

At Gebrüder Weiss, the planning and installation of the solutions at the Memmingen, Wolfurt and Aldingen sites is recalled equally positive. "The projects ran smoothly and lasted three months each", says project manager Diana Koplenig (pictured right). "DIVIS has adapted very flexibly to the schedule changes that occurred at the new building in Memmingen," emphasizes Koplenig.

Conclusion

With CargoVIS, Gebrüder Weiss has significantly accelerated its processes, minimized complaints and further improved service quality. "The video surveillance is highly valued by our customers and partners CTL and Dialog and is just as indispensable for us as a fire alarm system," says Markus Nigsch in a nutshell.

BACKGROUND

Gebrüder Weiss

Gebrüder Weiss is the oldest transport and logistics company in Austria and still family-owned (Weiss and Jerie families). The history of the logistics service provider goes back to the year 1330. Today, the Gebrüder Weiss (GW) Group headquartered in Lauterach (Vorarlberg) employs more than 6,500 people at 150 locations. GW is represented in Central and Eastern Europe in Austria, Switzerland, Germany, Italy, the Czech Republic, Slovakia, Hungary, Slovenia, Croatia, Serbia, Bosnia-Herzegovina, Bulgaria, Romania and the Ukraine. In fiscal year 2016, the partner of the general cargo cooperations CTL and Dialog generated a sales volume of € 1.36 billion.

The central IT services department of the globally operating company is located in Kennelbach. From here, not only branch offices of Gebrüder Weiss in Austria are managed, but also the worldwide network of the transport and logistics company.

Case study video & photos

Markus Nigsch

Authorized signatory at Gebrüder Weiss

photo© Gebrüder Weiss

Thomas Schneider

Plant manager at Gebrüder Weiss

photo© Gebrüder Weiss

Patrick Pflotsch

IT Service Desk at Gebrüder Weiss

photo© Gebrüder Weiss

Diana Koplenig

Project Manager at Gebrüder Weiss

photo© Gebrüder Weiss