DIVIS closes another gap in seamless delivery tracking

Bordesholm, January 31, 2017

With Scale+ ,CargoVIS II now offers not only another function to save time and money. The new module also supports your quality assurance and customer service. At the same time, it is noticeably improving the situation when it comes to recourse claims.

In this situation our new software module Scale+ offers different advantages!

More overview, less costs - interruption of the flow of goods is not necessary

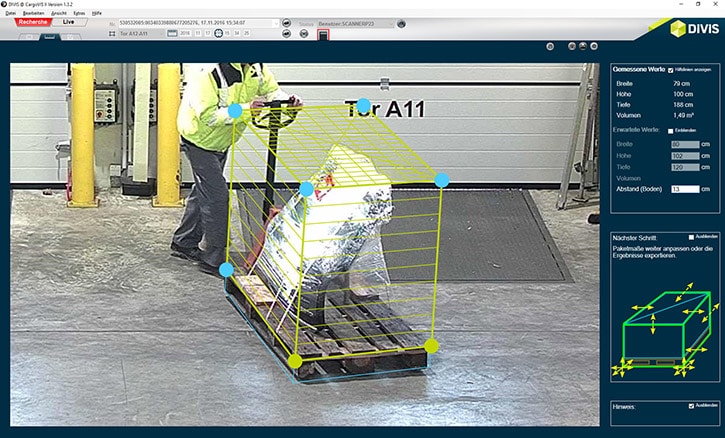

The software-driven volume control with Scale+ is based on the evaluation of the video material of your loading processes, previously recorded with existing cameras. Point-accurate controls can be performed by measuring an image of the package in the software. This streamlines your internal processing. At the same time, the module allows for more controls and ensures more transparency in your logistics chain.

New and unique at the moment: Reliable control even with stacked goods

Outstanding flexibility is demonstrated by Scale+, in particular, in the intelligent input of the difference in height, which allows even the precise control of packages placed on other consignments.

Strengthened evidence and better documentation: Efficient volume control is also possible at a later time

The truck has left your warehouse and is already on the road with the shipment heading to the customer. The Scale+ module makes it possible to check any packages from this load later. Simply select the desired package from the video recording in the software and carry out your inspection directly in the image.

Checks and proofs – really easy

After marking the desired package in the easy-to-use user interface, Scale+ displays the actual values in comparison to the nominal values from the forwarding software. You can also obtain this result in a clear PDF file or as .jpeg with your company data.

At the LogiMAT, we will be presenting our new software module Scale+ live alongside other DIVIS products and novelties.Visit us and take the opportunity to get to learn more about our CargoVIS II system solution and the new module!

We look forward to a personal talk with you!

You will find us at booth 7A07 in hall 7.

More info on the LogiMAT trade show: LogiMAT