Case Study

CargoVIS in general cargo handling

at Schmidt-Gevelsberg GmbH

"Thanks to the camera system,

no time sensitive shipment is left

behind. Every consignment and

every single package finds

its loading gate in due time

until the departure time.”

Andreas Berghaus

Head of the cross dock

in Schwelm

Schmidt-Gevelsberg GmbH

June 18, 2019

Schmidt-Gevelsberg GmbH

Great appearance for small shipments

Schmidt-Gevelsberg GmbH Internationale Spedition operates a modern logistics center on a 8,500 m² transshipment area at its main site in Schwelm. In 24-hour operation over 5,000 national and international shipments are handled here every day. The most important goals of the logistics experts from Schwelm are, on the one hand, the streamlining of the processes in the hall and, on the other hand, theft deterrence.

Almost a decade ago, the system partner of the CargoLine general cargo co-operation decided to use an intelligent, internal tracking system from DIVIS for the safe handling of logistics processes. As part of the cooperation, not only the video management solution CargoVIS was implemented. In the coming years the modules Location+, Text+, Gate+, Load+ and the application TagWatch* were added. The sophisticated asymmetric segments of the three halls as well as the outdoor area and underground parking lot were also equipped with a total of 170 networked cameras.

Andreas Berghaus, manager of the transshipment warehouse in Schwelm, explains the advantages of the video solution: "We handle over 5,000 shipments a day with more than 9,000 packages. More than 160 local traffic drivers ensure that the shipments are delivered on time every morning. Five warehouse control center employees work with the camera system alone every morning for three hours to show the drivers the shipments they have to deliver. Without the camera system, many shipments would not go to delivery because the drivers would not find them in time.

“Even if a package has been completely misplaced, possibly even in another hall, it will of course be found, and in time. Thus, we now reach delivery rates of well over 99 percent."

He continues: “Alternatively, drivers would have to scan each package to see if it is part of their delivery or not. This is almost impossible with the amount of packages on our 8,500 square meters.”

Andreas Berghaus proudly emphasizes: "Even if a package has been completely misplaced, possibly even in another hall, it will of course be found, and in time. Thus, we now reach delivery rates of well over 99 percent. In my opinion it would be impossible to achieve these delivery rates without a good camera system."

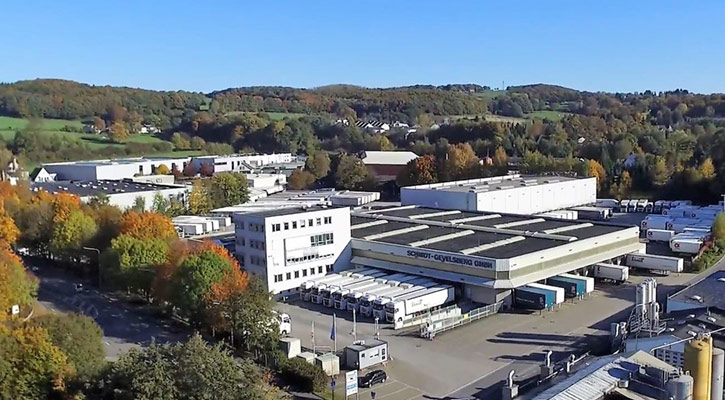

Fig.: Schmidt-Gevelsberg logistics center Schwelm

Also the evening unloading runs smoothly with CargoVIS in Schwelm.

"Thanks to the camera system, no time sensitive shipment is left behind. Every consignment and every single package finds its loading gate in due time until the departure time. The excuse “could not be found”, does not count, "says the warehouse manager.

At Schmidt-Gevelsberg, the video solution from DIVIS is used in a wide range of areas, including the claims department and the service department.

Especially the sensitive issue of claims settlement has benefited from the DIVIS solution, says Berghaus. Discovering and documenting whether a damage had already occurred to the goods when they reached the warehouse. Thanks to video management no problem.

"Especially in the last months and even years, we have optimized a lot in terms of the entire time schedule in our transshipment warehouse."

The camera system is a valuable instrument for analyzing flow rates of goods, time schedules and optimization potential, according to Berghaus.

Thanks to intensive research with the video solution, improvements could be implemented at Schmidt-Gevelsberg across the entire company organization.

Optimized were:

- Personnel deployment planning

- Indoor and yard use

- Changing hall occupancy due to fluctuating flow rates of goods

- Departure time control

- Assignment plans and gate assignments with corresponding monitoring of compliance (thus faster and more efficient goods handling)

The advantages of video analysis are obvious to Andreas Berghaus: "Through daily analysis of the processes, especially the flow of goods, we can make adjustments at any time to achieve better results. We can respond better and faster to the smallest change.

All these optimizations could only be achieved by a well-functioning camera system. The alternative would have been that several employees would have had to constantly monitor the processes, uninterrupted over days and nights at various points in the company. "

At Schmidt-Gevelsberg, modern video management means that the growing flow of goods and other logistics challenges will continue to grow in the future.

Finally, Berghaus emphasizes that even the last goal, theft prevention, could be achieved thanks to the video solution: "Due to the good camera surveillance, we have zero losses. There is no theft at our premises and no loss of goods due to other causes."

"Through daily analysis of the processes, especially the flow of goods, we can make adjustments at any time to achieve better results. We can respond better and faster to the smallest change."

Further optimizations ...

Schmidt-Gevelsberg expects further optimization of the processes in the hall from the CargoVIS module CargoVIS-Modul Link+. Its implementation is planned this year. Using this module, drivers can then independently view a picture of the package on the PC without having to go to the warehouse control room staff. This will further streamline operations and save even more time.

*TagWatch manages location tags and checks the availability of tags in the system. The tool can be started directly from CargoVIS.

BACKGROUND

Schmidt-Gevelsberg GmbH

Cargoline partner Schmidt-Gevelsberg is one of the most traditional forwarding and logistics companies in Germany. Founded in 1893, the service provider today employs more than 320 people. At the main site Schwelm there is a modern logistics center, which was expanded largely in 2005 (8,500 m² handling area and 88 gates). In 24-hour operation over 5,000 national and international shipments are handled here every day. The logistics center in Sprockhövel has an additional 13,500 m² of logistics space, 2,500 m² of office space and more than 20,000 pallet spaces for every requirement of state-of-the-art contract logistics. Through its network partners, Schmidt-Gevelsberg has access to numerous other transhipment and warehouse locations throughout Europe.